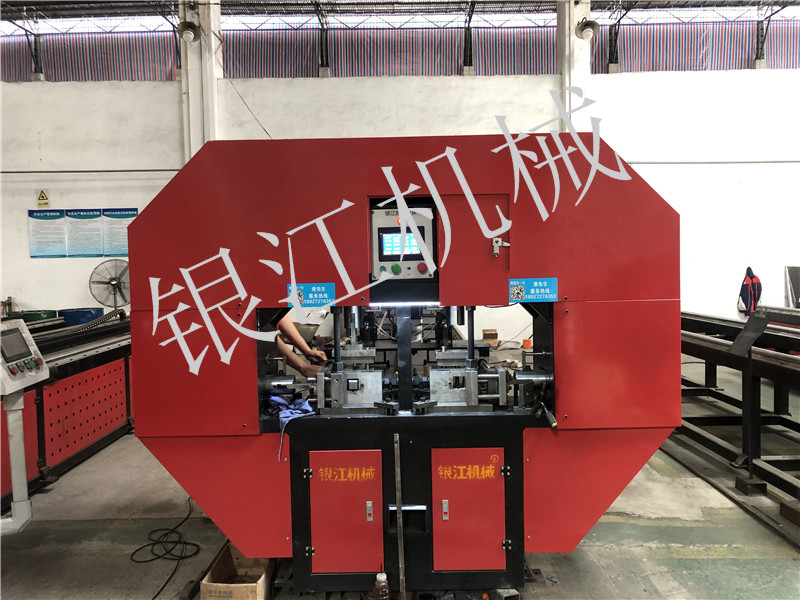

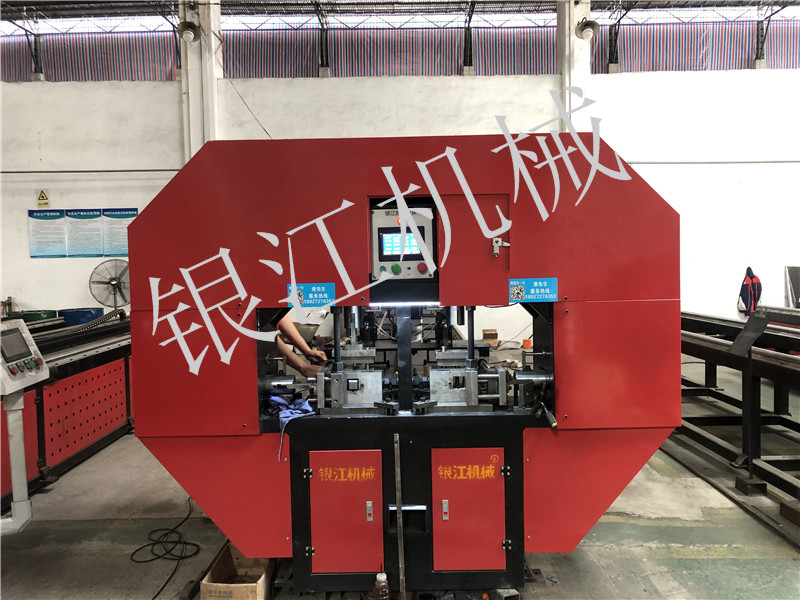

台机台整体放上意大利CNC大型龙门铣从头到尾铣精铣过,全部螺丝孔打点攻牙和安装配件位置以及安装直线齿条L型的凹槽都是一次性精铣出来,确保安装齿条和直线滑轨三点平衡度能从头到尾保证0.05C

以内。

高效、高品质、安全、稳定、易维护、易操作、易学易懂,油缸想快就快,想慢就慢,压力够足够稳,模心自动保护,

自动排料,省电节能环保,省地方,省人工,省钱,解决爬架数控冲床AC伺服马达,经发黑处理加硬高精度齿条,配合直线导轨,送料精准稳定,送料速度可达500mm/s以上(较

The body frame of punching machine is made by welding square tube and the frame is covered with plate.Thanks to this

body frame, the punching machine can work very stably and the sliding rail vibrates very little when it works at high speed.

The finish-milling is made to the whole body frame of punching machine using the large CNC plano miller that is made

in Italy. All bolt hole (including drill locating hole and tapping),locating hole for installing parts and L shape groove for

installing linear rack are finely milled at one time. The balance degree between linear rack and linear sliding rail can be less

than 0.05C from beginning to end.

还不一定能对准模,冲孔难拉管,容易卡模,管子容易变形,冲出来起毛刺,占地面积大,容易工伤,操作难等问

题。本机器都可以解决。节省人力:设备自动运行送料,自动计算孔距,自动冲孔,自动冲断。节省计算时间:电脑自带记忆系统,可存储多套冲孔冲断数据。

节省大量定位时间:气动夹钳,力度大,自动校位不跑偏。节省换模时间:使用快捷更换模具结构,插管自动校正。提高生产效率:数控冲床与普通冲床相比,一机多用,冲孔冲断一次完成。安全系数提高:生产操作员实现离机操作(可设定离机自动停),较大限度杜绝安全事故。

8

8